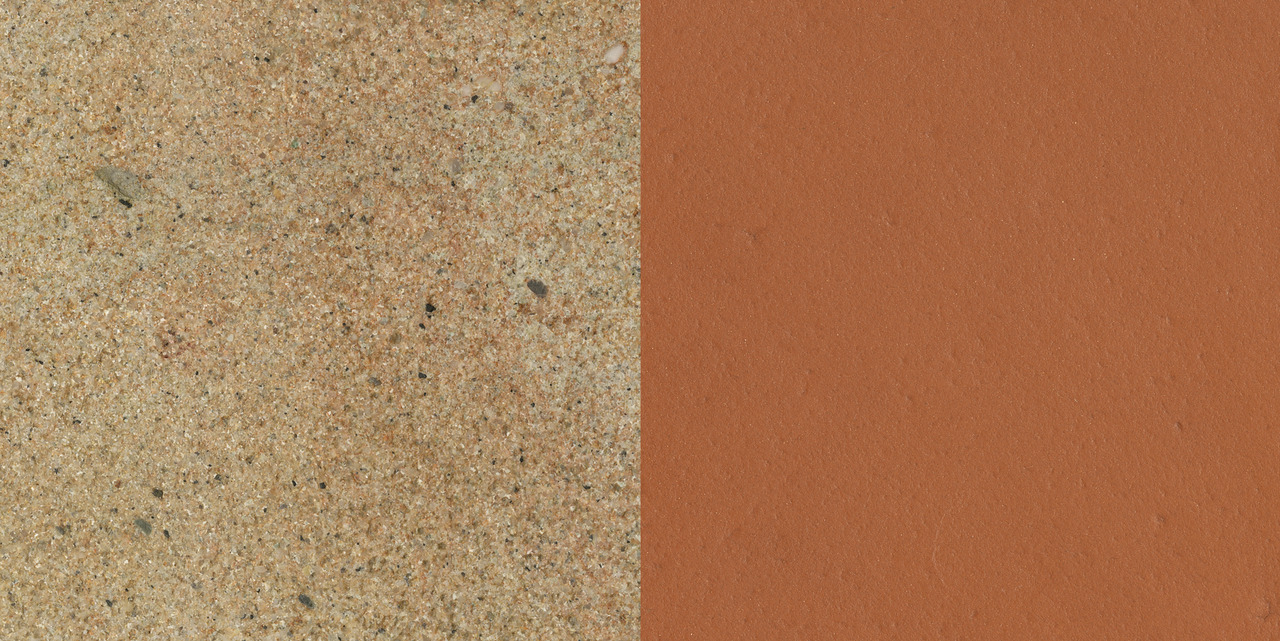

Ideal for protecting microporous stone and terracotta surfaces

Clear, satin natural oil impregnation penetrates in the microporous surface and will not form a film on the surface. Through the impregnation with Osmo Stone and Terracotta Oil, the microporous surface becomes water and dirt repellent as well as stain-resistant. Dust resulting from screed and concrete surfaces is greatly reduced.

Osmo Stone and Terracotta Oil is suitable for the clear impregnation of microporous natural stone with a polished, sanded or break surface and artificial stone in outdoor areas. Especially suited for paving and windowsills made of granite as well as limestone and slate.

Ingredients

Based on natural plant oils (sunflower oil, soybean oil, thistle oil), paraffin, siccatives (drying agents) and water-repellent additives. Dearomatised white spirit (benzene-free). Detailed declaration of ingredients available upon request.

Storage

5 years or longer if stored in the originally closed container. If thickened by frost, store at room temperature for 24 hours prior to use.

| COLOUR CODE | CAN SIZE LITRE | ARTICLE NUMBER | |

|---|---|---|---|

| 0.75 | 11500112 | |

| 2.50 | 11500113 |

NUMBER OF COATS

Two coats on an untreated substrate; for renovations, normally one coat on the clean surface is sufficient.

Surface preparation:

The surface must be asorbent, clean, dry and frost-free. Osmo Stone and Terracotta Oil is ready to use; do not thin. Stir well.

Impregnation results vary greatly depending on the substrate and the surface condition. Therefore a trial application is always required. Product coverage varies greatly depending on the absorption properties of the substrate. Very dense and polished stone absorbs only maximum half of the stated amount of oil, whereas absorbent concrete or break surface stone absorbs up to double the amount of oil.

Methods of Application:

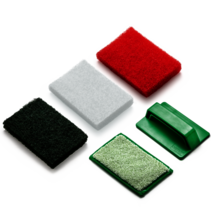

With Osmo Flat Brush, Floor Brush, Oil Finish Applicator Fleece (Hand Pad Holder) or Microfibre Roller, apply very thinly and spread well. Remove any excess product (pooling or streaking) with a pad or a lint-free cloth. For larger areas, remove excess oil with a rubber scraper and polish with a buffing machine (white pad). Important: the liquid oil must be absorbed into the surface. There must not be any oil left on the surface. Allow to dry for 8-10 hours. Ventilate well while drying. Apply the second coat also very thinly. Again, remove any excess. When renovating already oiled surfaces, normally one coat on a cleaned surface is sufficient.

Cleaning of tools:

With Osmo Brush Cleaner (free of aromatic compounds).

Drying time:

Approx. 8-10 hours (normal climatic conditions, 20-23°C/ 50-65% rel. humidity). Ventilate well while drying. Lower temperatures and/or higher air humidity may increase drying times significantly.

Note:

Oils enhance the natural colour of the substrate (permanent wet effect). Trial application is absolutely essential! Impregnation may influence the slip resistance of the original surfaces. White or very light-coloured stone/surface may yellow slightly as result of the oil treatment! The acid sensitivity of the stone (e.g. marble) remains unaffected. Non-absorbent surfaces, such as glass, glazed tiles or ceramic, cannot be treated (impregnated). Substrates sensitive to solvents (e.g. plastics such as Plexiglas) must be protected. A lack of ventilation leads delays in drying.

Caution:

Keep out of reach of children. Safety data sheet available on request. Warning: Materials impregnated with liquid product, such as cloths, may self-ignite. After use, let the materials to dry completely either spread out flat or in a closed metal container and then dispose of them properly. EU VOC limit value for this product: out of scope.

Disposal:

Dispose of product residues according to the official guidelines (European Waste Code (EWC)-Code 08 01 12). Only completely emptied cans can be recycled.

HOW MUCH COATING DO I NEED?

With our finish calculator, the right amount of coating necessary for your project can be calculated quickly and easily.

Please follow our advice in the product information sheets for the correct application.