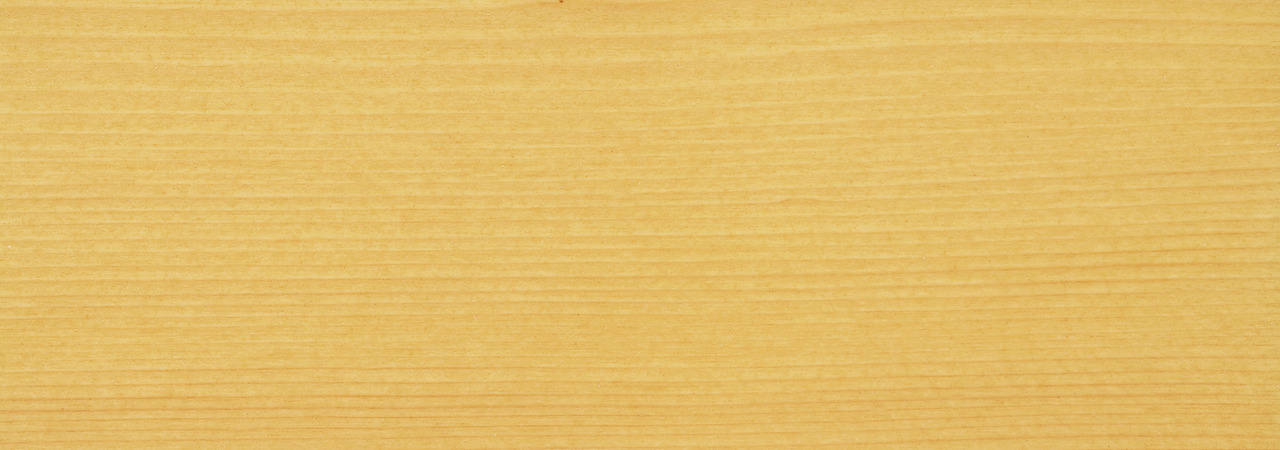

Protected prefectly against the sun – clear or transparent, lightly pigmented UV protection for outdoor areas!

Clear or transparent, lightly pigmented wood coating based on natural oils for wood in outdoor areas. Matt or satin. Microporous surface allows the wood to breathe and reduces swelling and shrinkage. Water repellent, will not crack, peel or flake. Simply recoat without sanding. Easy and seamless application. Coating stays workable while coating. When used alone, it blocks the greying process on vertical surfaces with a UV protection factor 12 in comparison to untreated wood. The coating contains active ingredients to protect the coating against mould, algae and fungal attack.

Osmo UV-Protection-Oil Extra is ideal for all vertical wood surfaces in outdoor areas: doors, windows, window shutters (dimensionally stable elements), carports, timber cladding, balconies, fences, pergolas, and garden sheds (dimensionally unstable elements).

Ingredients

Based on natural plant oils (sunflower oil, soybean oil, thistle oil and linseed oil), iron oxide and organic pigments, titanium dioxide (white pigment), siccatives (drying agents) and additives, biocidal active ingredient: 3-iodo-2-propynyl butylcarbamate (IPBC). Dearomatised white spirit (benzene-free). Detailed declaration of ingredients available upon request.

Storage

5 years or longer if stored in the originally closed container. If thickened by frost, store at room temperature for 24 hours prior to use.

| COLOUR CODE | CAN SIZE LITRE | ARTICLE NUMBER | |

|---|---|---|---|

| 0.75 | 11600026 | |

| 2.50 | 11600027 | ||

| 0.75 | 11600049 | |

| 2.50 | 11600057 | ||

| 0.75 | 11600033 | |

| 2.50 | 11600034 | ||

| 0.75 | 11600062 | |

| 2.50 | 11600063 | ||

| 0.75 | 11600068 | |

| 2.50 | 11600069 | ||

| 0.75 | 11600041 | |

| 2.50 | 11600042 | ||

| 0.75 | 11600051 | |

| 2.50 | 11600052 | ||

| 0.75 | 11600081 | |

| 2.50 | 11600082 | ||

| 0.75 | 11600092 | |

| 2.50 | 11600093 | ||

| 0.75 | 11600104 | |

| 2.50 | 11600106 |

NUMBER OF COATS

Two coats on raw wood; for renovations, normally one coat on the clean surface is sufficient – without sanding!

Surface preparation:

Wood surface must be clean, dry and frost-free (moisture content max. 20%). Osmo UV-Protection-Oil is ready to use. Do not thin. Stir well before use. If possible, please apply the first coat to all sides before installation. For renovations, clean old microporous stains thoroughly - if necessary, sand lightly. Revive any already greyed wood with Osmo Wood Reviver Power-Gel before applying. Old paints, varnishes and lacquers must be completely removed. Always wear a dust mask while sanding. Do not sand smooth surfaces finer than P120. Fresh wood containing natural wood extractives and especially hardwood need to weather (for approximately 6 weeks) after installation. Through weathering, the wood becomes absorbent and the wood coating adheres optimally.

The finished surface and the product coverage are influenced by several factors, including the condition of the wood. Therefore, a trial application is always required, especially for unfamiliar surfaces.

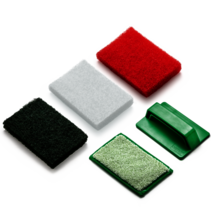

Methods of Application:

With Osmo Flat Brush or Microfibre Roller, apply thinly along the wood grain and spread very well. Also spread well into corners and curves. Leave to dry for approx. 12 hours. Ventilate well. Then apply the second coat also very carefully. With a coloured UV-Protection-Oil Extra as the first coat, the second coat can also be carried out with a clear UV-Protection-Oil Extra. When recoating colour treated surfaces, or for renovations, one clear coat applied to the clean and dry surface is usually sufficient.

Cleaning of tools:

With Osmo Brush Cleaner (free of aromatic compounds).

Drying time:

Approx. 12 hours (normal climatic conditions, 20-23°C / 50-65 % rel. humidity). Ventilate well while drying. Lower temperatures and/or higher air humidity may increase drying times significantly.

Note:

We recommend inspecting the coating regularly (min. 1x annually, in particular areas exposed to weather). If necessary, clean the surface and recoat 1x thinly with Osmo UV-Protection-Oil Extra. Horizontal elements mounted onto vertical wood should have at least a 15-degree angle. Sharp edges must be rounded off to a radius of > 2 mm. If the natural greying process has already begun, revive the surface with Osmo Wood Reviver Power-Gel and apply 2 coats of a clear or coloured Osmo UV-Protection-Oil Extra. To achieve the UV protection factor 12, it is necessary to apply 2 coats of UV-Protection-Oil Extra. With only one coat or by using a clear UV-Protection-Oil Extra as the second coat on untreated wood, the life of the coating is significantly shorter. Osmo UV-Protection-Oil Extra contains biocides and therefore it is only to be used in outdoor areas. The added active ingredients delay or minimise the risk of algae and fungal attack. For effective protection, two coats are to be carried out. In accordance with the latest technical research, permanent protection against algae and fungal attack cannot be provided. Osmo UV-Protection-Oil Extra 429 Natural protects wood nearly invisibly. It does not enhance the wood colour – the natural wood colour is preserved (no permanent wet effect). On dark or reddish wood species, Osmo UV-Protection-Oil Extra Natural is visible as slightly white chalky surface. A trial application is always recommended.

Caution:

Harmful to aquatic life with long lasting effects. If medical advice is needed, have product container or label at hand. Keep out of reach of children. Avoid release to the environment. Contains 3-Iodo-2-propynylbutylcarbamate (film protection). May produce an allergic reaction. Warning: Materials impregnated with liquid product, such as cloths, may self-ignite. After use, let the materials to dry completely either spread out flat or in a closed metal container and then dispose of them properly. EU limit value for this product (cat. A/e): 400 g/l VOC. This product contains max. 400 g/l VOC.

Disposal:

Dispose of product residuals according to the official guidelines (European Waste Code (EWC)-Code 08 01 11*). Only completely emptied containers can be recycled.

HOW MUCH COATING DO I NEED?

With our finish calculator, the right amount of coating necessary for your project can be calculated quickly and easily.

Please follow our advice in the product information sheets for the correct application.