Extremely high filling strength, short drying times, good sanding properties.

Universal polymer dispersion for filling cracks and joints in sanded parquet. Extremely high filling strength, short drying times and good sanding properties create a quality product. Osmo Wood Putty is combined with sanding dust, and thus it offers a big advantage in that it matches the colour of subsurface exactly.

Suitable for filling small cracks (< 2 mm) and small damages (e.g. screw holes) in wooden flooring and parquet. Can be used universally on all wood species. Not suitable for elastic constructions, e.g. plank, sprung, raised and false floors as well as cork flooring.

Ingredients

Polymer dispersion, bulking agent, emulsifiers, water, preservatives (MIT/BIT). Detailed declaration of ingredients available upon request.

Storage

12 months or longer if stored in the originally closed container. Do not expose to frost or temperatures above 30 °C!

| COLOUR CODE | CAN SIZE LITRE | ARTICLE NUMBER | |

|---|---|---|---|

| 1.00 | 13500025 | |

| 5.00 | 15100025 |

Surface preparation:

Wooden flooring to be filled must be sanded down to the raw wood surface and must be free of oils, fat and other dirt. The final sanding step before filling with Osmo Wood Putty should be carried out with a belt sander (e.g. P80) and an edge sander P60. Thoroughly vacuum the surface before applying putty. Note: Do not add sanding dust with remnants of old coating to Osmo Wood Putty; only use clean sanding dust.

Methods of Application:

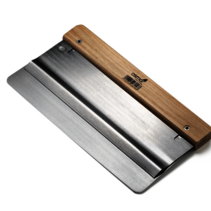

Before preparing the putty in a bucket, stir well and ensure that all sediment is mixed into the putty. Create a thick, easy-to-trowel paste by adding sanding dust (approx. 15 % weight increase). If possible use sanding dust (grit P 80-120) from the same wood species. Crucial for a flawless application is the right consistency. If too thick, adhesion to wood will be insufficient and putty may be removed when sanded. If too thin, holes will be left unfilled. Fibrous sanding dust, especially from exotic wood species, can lead to bad mixing properties and may prevent joints from being filled. In such cases, reduce the amount of sanding dust. We recommend stirring sanding dust and putty into a homogenous paste in a separate container. Fill flooring diagonally with Osmo Double Blade Scraper or a rust-free trowel and press firmly into joints. Repeat if necessary. After 30-60 minutes the dried paste can be sanded, first with a coarse grinding medium (grit P 80) and then with a fine grinding medium (grit P 100 – 120), so that no putty residues are left on the wood surface. Mostly fine sanding with P 100 – 120 is sufficient. Surface coating can be carried out with an oil-and-wax-based finish from Osmo. Remove any Osmo Wood Putty deposits quickly with water.

Cleaning of tools:

Immediately after use, with soap and water.

Drying time:

Approx. 30-40 minutes (normal climatic conditions, 20-23°C/50-65 % rel. humidity). Ventilate well while drying. Lower temperatures and/or higher air humidity may increase drying times significantly.

Note:

As the wood putty mixture and processing depend significantly on wood species and sanding dust, a trial application is absolutely necessary! Do not fill joints in sprung or plank flooring!

Caution:

If medical advice is needed, have product container or label at hand. Keep out of reach of children. Contains benzisothiazolinone (BIT), methylisothiazolinone (MIT) (preservatives). May produce an allergic reaction. Safety data sheet available on request.

Disposal:

Dispose of product residuals according to the official guidelines (European Waste Code (EWC)-Code 08 01 20). Only completely emptied cans can be recycled.

HOW MUCH COATING DO I NEED?

With our finish calculator, the right amount of coating necessary for your project can be calculated quickly and easily.

Please follow our advice in the product information sheets for the correct application.